Concrete Pumping Derby - Affordable Concrete Pump Hire

PHONE: 0115-824-3549

Concrete Pump HireConcrete and Screed Pumping Services operating around Derby

Let us take the strain, Pumped to exactly where you like. No backbreaking dangerous wheelbarrow runs Experts at reaching difficult areas and inaccessible places

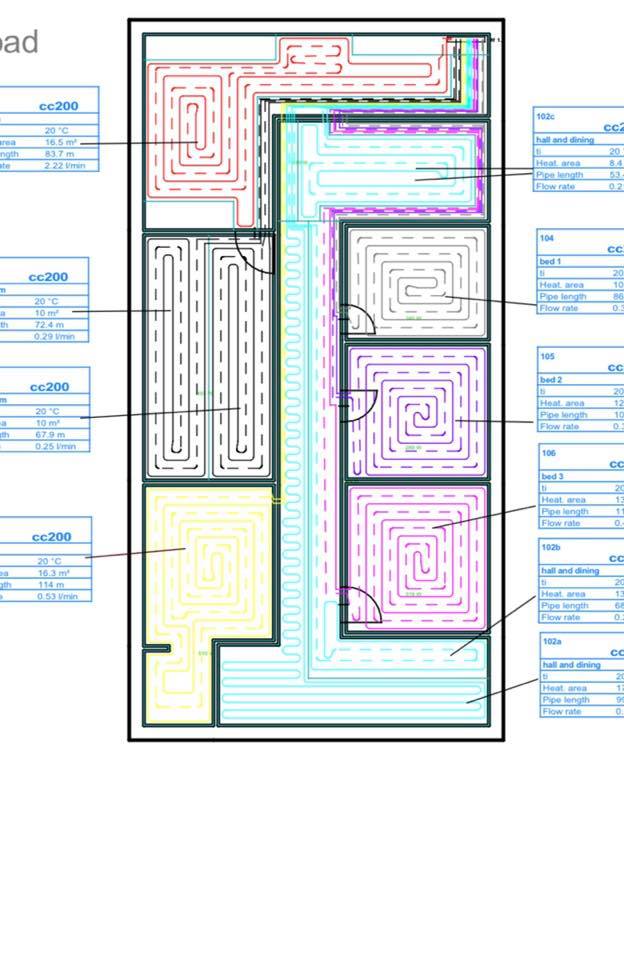

One-stop-shop for screed flooring Take advantage of our full screed laying service, we can prepare, supply, pump and lay whichever product you choose. Also we can design and install a full underfloor heating system to your exact requirements. Underfloor Heating Call now for a free consultation and we will design your underfloor heating with free CAD drawing. Our experts will advise on the best screed product for your project. Other Services that we Offer

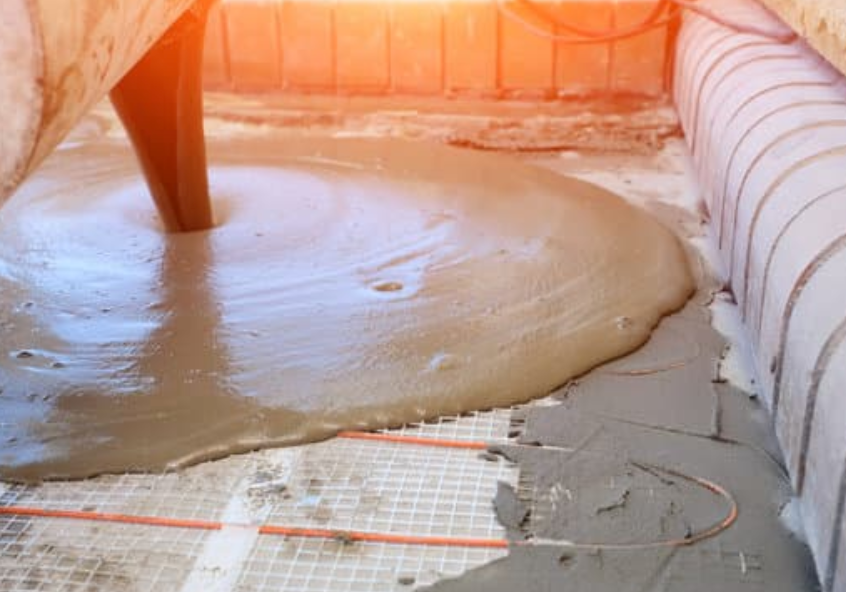

Save Time Energy and Money We enjoy saving our customers time, energy, hassle and money. Manual labour laying foundations, subfloors, concrete slabs and bases can be a back-breaking, time-consuming and messy experience. Lumping all those bags of cement, shovelling sand and carrying buckets of water. Not to mention wheelbarrow runs and levelling everything. Wouldn't you agree? hard graft and lots of man-hours. Liquid Concrete Pumping Why not get a price from us to pump our liquid concrete product to exactly where you require. Our pump operator and the team will oversee the project from start to finish. They will pump, level and lay the liquid concrete product to perfection, no mess, no fuss, and saving you time and man-hours. Screed Pumping We supply and pump all types of flow and liquid screed products. These versatile screeds can be used in all manner of flooring applications, both in commercial and residential buildings. They are expertly designed and provide a smooth surface when dry, ideal for covering underfloor heating and a base for numerous other floor material coverings. Screed Floor Benefits Liquid flow screeds, which there are many different types, depending on your project requirements. The more underfloor heating systems that we install these days, make liquid screed an ideal covering material. The benefits are, it can be laid fast, laid thinner, superior thermal qualities, so more energy efficient. To top this, liquid and flow screeds have very low shrinkage values and cracking is minimal if any at all. PHONE: 0115-824-3549 Our Concrete and screed pumping services stretch right around the Derbyshire and Derby City area, including all local surrounding villages. We can supply and pump the concrete or screed product of your choice to your desired location, either for domestic or commercial usage, building works, factory, office flooring or special chosen project. If you are looking for a trustworthy liquid concrete or flow screed pumping company with fantastic prices and a first class customer service attitude, well you have landed in the right place. I assure you every customer is important to us and we have a reputation to keep. PHONE: 0115-824-3549 Ring through with your project measurements or contact us for a site visit and we will work out an approximate price. Our company has a vast experience with concrete and screed products in the Derby area, spanning over 15 years in the industry. So you can rest assured that you will be taken care of from start to finish. We would like you to recommend us to friends and family, most of our work is through referrals of customers that have used our Concrete services before. PHONE: 0115-824-3549 Concrete Derby This versatile man made material is the most used mixture on earth so far. It has so many uses i cannot see it drop in popularity in the foreseeable future, unless another and better substance is invented to take its place. Concrete is a mixture of course and fine aggregates combined with cement dust, when water is added it becomes a slurry which can be poured and then formed in many ways. The mix reacts with the water which eventually hardens the mix. Other elements like steel mesh can be aded to large areas to reinforce the structures. An extremely durable and weatherproof material that is used extensively all over the world for small domestic projects to massive structures that stand the test of time. No wonder it's a firm favourite with the construction companies all over the world. It makes economic sense to use concrete products on these large man made structures as it's easy to manipulate into any shape while wet, and once dry it forms a strong element proof shield. It depends on what exactly you will be using the concrete for, sometimes a quicker drying concrete will be required, say for fence posts or holes in the ground, anything that needs fixing quickly with added strength.

PHONE: 0115-824-3549 Ten Good Uses for concrete 1. Excellent choice for strong structures 2. User friendly and malleable easy manipulated when in liquid form 3. Relatively cheap compared to some building materials 4. Usually made from locally sourced materials, good for the environment 5. Very durable and lasts a considerable longer time than most organic materials. 6. A good product that is waterproof and withstands most things the elements throw at it 7. The strength of this material just gets better over time as it dry out and the moisture is eradicated. 8. Different textures can be created on the surface to give a whole new look and design 9. Concrete does not deteriorate like most organic compounds, it holds it strength for many years and does not rot or breakdown when submerged under the ground 10. Concrete can actually be re-cycled when finished with, example, broken down and used in the structures of other building, or ground back down to be used as new concrete. PHONE: 0115-824-3549 Screed Supplier Derby Screed is a smoother mix of sharp sand and cement unlike concrete which has larger particles for added strength. Screed is best used on when a flat and level finish is required, usually laid on top of a concrete sub base so it can be levelled flat, maybe to take a covering later of floor boards, carpet or laminate flooring as an examples. Screeds are mainly used internally for flooring, sometimes to cover underfloor heating systems or to supply a thermal or an acoustic effect. Some Screeds that are required externally will have polymers added to give a stronger and more hard wearing surface, as well as a quicker drying area if needed. Ten Good Uses for Concrete Screed Smooths out Concrete floors Levels Out Flooring Conceals under floor heating pipes Good base for applying tiles Screed Staircase construction Cheap surface when polished in a raw state or colours added External Strong Smooth surface (when other materials added) Can come in different strengths depending on usage Can be a quick drying surface with additives if needed. Can be laid quiet quickly if desired Thank You from Nottingham Concrete and Screed Phone: 0115-824-3549Pumping screed and flow screed

Our company offers a complete precision flow screed service for screed floors using anhydrite screeds and concrete floor screeds. We also provide our customers with advice based on their unique projects. We have immersed a massive wealth of experience in pumping, levelling, and handling flow screeds. We are also often recommended by contractors because of our proven professionalism and expertise. We work in versatile business sectors, whether commercial, residential, or government contracts. We also have a compact truck mounted with concrete pumps as well as specialised screed pumps. As a result, we can provide a more comprehensive and reliable service to our customers. We are also capable of supplying and pumping our screeds directly to your site. Our work will leave your site with minimal mess and fewer labour costs. Our Pumping screed and flow screed Services Before we offer our screed services, we provide an additional optional setup and preparation service. Through this service, we take care of all floor screeding preparation needs. We also install underfloor heating for projects that require assistance. We then work to ensure that your flow screed is pumped to the designated areas. We work on your floor within a 24 to 48-hour foot traffic. Once the screeding process is complete, we return at least one week later to provide our floor sanding service and laitance removal. This ensures that floor coverings like tiles and karndean will stand easily. We have a vast range of specialised equipment for all our services. We also ensure that your floor is even and smooth, making it perfect for any of your finishes. PHONE: 0115-824-3549 Our flow screed services are also either floated, un-bonded or bonded. We are mostly focused on providing:

Fast-drying Liquid screed Liquid screed is a new development that is used to install screed for new floors in a renovation or a new building. We have approved suppliers and installers of the fast-drying liquid screed. While new, it has the same characteristics as the standard anhydrite liquid screeds. However, the fast-drying liquid screed is cement-based. Therefore, it has fewer issues of surface laitance removal. For instance, the optimal time that the fast-drying liquid screed takes to dry is 14 to 21 days. This is twice as quick as traditional liquid screeds. Hence, our fast-drying liquid screed services are perfect for customers that are working on a schedule. Ultra-thin screed We have an ultra-thin liquid screed that can be applied to a minimum of 12mm in depth. As the only manufactured screed of this capacity, we use it to bridge the gap between the bonded screed and smoothing compounds. We are also capable of providing you with pump-able, thin, and flow screed that can achieve surface regularity. Our ultra-thin liquid screed is of high quality. Readily mixed, the screed will cover 83m2 of space for every cubic meter of the screed. Hence, it is an excellent alternative to expensive screed options. PHONE: 0115-824-3549 Why You Should Consider Liquid Screeds The nature of the flowing screed makes it friendlier to work with: it is easy to pour, we can get the screed to the required location quickly, and the fill out process is fast as well. Besides, flow screed reduced the amount of physical labour needed. Additionally, since the screed is pumped directly to the required location, less equipment is used for the flooring process. This means that there will be fewer objects to interfere with the finished work. Also, our pumps can install the screed quicker: it allows the drying stage to start earlier than usual, and in turn, you get your finished product faster than is expected. The flow screed also has a form that settles at a consistent level without the need for intervention. Your finish will be closer to perfect. If you want, we can use a machine to polish your results. The Benefits of Using Flow Screed Once the flowing screed is on your floor, certain advantages are experienced that traditional screed methods cannot beat. These include:

Minimal shrinkage, cracking, and curling When the screed is poured, there are fewer factors that cause oxygen to gather. Usually, the oxygen is stored within the screed when it is pouring. Flow screed captures a smaller volume of oxygen than traditional screed methods. This is because the conventional methods have sand within the cement. The sand particles help to capture more oxygen amounts. Once the screed is poured and relaxed, any oxygen present will rise through the solution, trying to find a release. The amount of oxygen released will determine the size of the screed shrinkage. Therefore, since flow screed has less oxygen present, it experiences minimal shrinkage. Moreover, the flowing screed can release trapped air within without human intervention. This is due to its self-curing and self-compacting nature. This also allows the flowing screed to reach the drying process faster. Besides, less shrinkage also results in minimal cracking and zero curling. PHONE: 0115-824-3549 Less installation time Since we use a concrete pump to apply the flowing screed, it becomes easy to cover a large region of flooring within a short period. The preparation time for standard concrete flooring can be extended. Our flow screed services have a 12mm-100mm coverage making it possible to screed over 2000m2 of the floor every day. This is ten times faster than the standard concrete flooring process. We also have foot traffic of within 24 to 48 hours. Easy application Flow screed is designed to leave you with an even and smooth surface. Hence, the application process is simple. This has made flow screed a popular product in many building projects. All you need is a concrete pump to pump out the screed. The preparation process is also easy. The only significant preparation required in the pumping and flow screed process is the floor preparation process. Also, it is vital to ensure every hole and crack is filled, and the floor is dried. PHONE: 0115-824-3549 Reduced labour and construction costs The method we use for the flow screed process requires very minimal manual labour. Therefore, you will complete the installation process without the need for reinforcement. We also cover about 100m2 in less than an hour. Flow screed has increased durability and strength. Hence, you can use it for great depths. The fewer materials used for flow screeds also make it a low-cost flooring solution. Improved underground heating performance One of the advantages you will have when you hire our flow screed services is the increase in the efficiency of your underfloor piping. The flow screed will keep your floor at the right temperature. Also, the screed will hold the temperature underneath. Liquid screed also has thermal conductivity. This means that the heat on your floor will be applied quicker. Besides, the deeper you go with your screed, the better your conductivity will be overall. This means that you will save more money that would have otherwise been spent on energy bills. Also, the heat will be distributed evenly in every room. Environmentally friendly process If you are into saving the planet, then our flow screed services are just the thing you need for your building projects. Flow screed is the next generation of green flooring. This is because it is comprised of recycled materials. Hence, our services will help you reduce your carbon footprint significantly. PHONE: 0115-824-3549 Quick-drying process Do you have a scheduled project? Are you running out of time? Then consider our flow screed services. We will help you reduce your building turnaround time significantly. Flow screed is a fast-drying cement-based screed with a quick application process. It is also the most accessible materials used in flooring. Within 24 hours of application, you can use the flowing screed. You will also be ready to apply your finishes after about 5 to seven days. Also, some of the materials used for flow screed processes can be force dried safely. Why You Should Choose Us We specialise in supplying and laying the different types of flow screed. We aim to meet all your flooring needs by providing the solution to even the hardest of jobs. Therefore, if you are:

We will get the screed to the trickiest of places. We also offer a complete and detailed survey for your projects. We have the right expertise and skill to ensure that all your flow screed needs are met with efficiency. Our customer service is also excellent. Therefore, visit our website today and get a quote on your pumping screed and flow screed needs. You can also call us; we are always ready to handle any of your concerns. Pre-screed preparation services Preparation is everything in the building game, and the laying liquid screed process is not an exception. The truth is, preparation in the screed laying process might be significantly important. After all, you do not want wet screed spilling and flowing all over your property. There are several steps that we take to ensure your floor is exceptionally prepared. We are also positioned to provide you with guidance on how you can prepare for your liquid screed. Our screed flooring is designed to ensure that the most testing conditions do not affect its standing. We also provide these services for customers that seek to utilize their underfloor heating. We help you save on your energy bills by providing liquid screed with a combination of materials, anti-shrinkage, and anti-crack agents of high quality. We guarantee long-lasting results with an increase of benefits when you get our concrete flooring. PHONE: 0115-824-3549 Our services We can provide you with a full preparation or a part preparation service. We tailor your preparation needs for your specific project. When you hire us:

Our preparation professionals are also well-skilled in advising on the correct application of primers, damp proof membranes, insulations, and sealers. Primers Primers bond the screed to the base of the floor. You will find different types of primers for the different types of screed systems and bases. Damp-proof membranes These are used to separate the insulation or screed from the concrete base. They also prevent the damp from rising. They exist in the form of polyethylene. Insulations Most of the heat lost in a room is lost through the floor. Hence, the work of the insulation is to prevent noise and thermal heat loss. Sealers These provide the dust proofing of a wearing screed. Hence, they are perfect for spaces where floor finishes are not applied. They are also used to harden the screed. Preparing Your Floor for Screed Getting the perfect floor can be achieved by first taking the right preparation steps. Our preparation process is divided into:

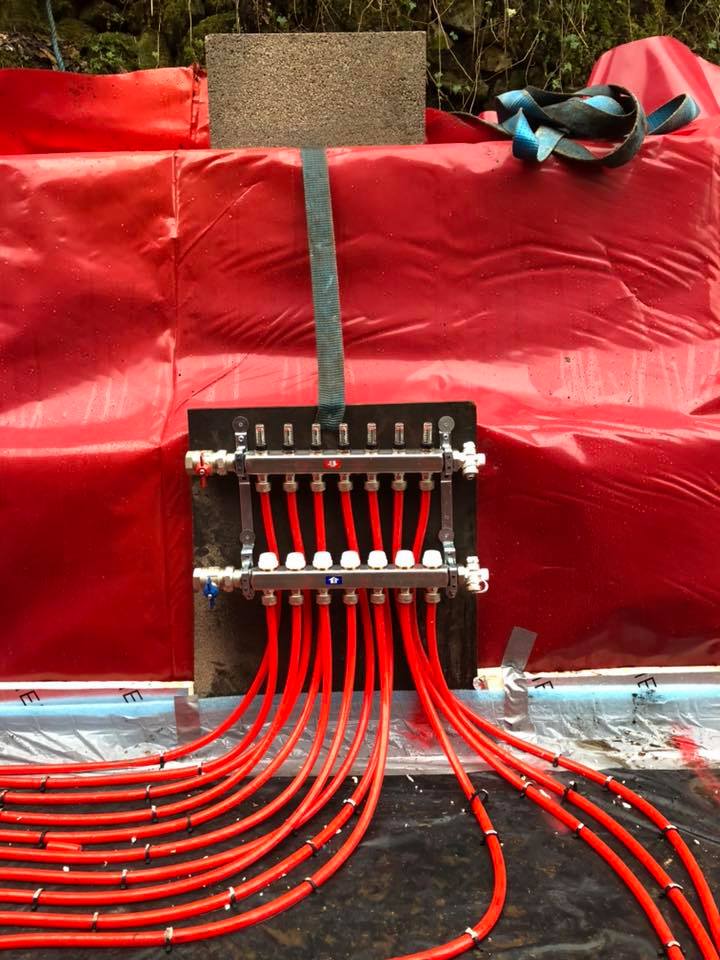

1. Measuring the amount of necessary screed We have a team of contractors that are highly skilled in this procedure. It is vital to measure the exact amount of screed needed for the floor. If you measure an amount that is too little, you will need more deliveries from your supplier before your current batch goes off. This can result in other problems. For instance, mixing in batches can result in inconsistencies. Also, we are assuming that another batch will be available on time. On the other hand, having too much screed is a waste of resources. Additionally, disposing of the excess screed can be difficult since no supplier is ever willing to take ready mixed concrete back. That is why we insist that you use our professionals. We will come to your location and do the measuring for you. We also advise that you ensure you have a hippo bag ready. Any excess screed can be poured into the container to collect the screed separate from the water. This makes it easy to dispose of hard screed. Also, the excess screed is always present in pipes and pumps. The bag will get rid of that as well. PHONE: 0115-824-3549 2. Removing present debris and laying out insulation It is also imperative to make sure that the area you want to screed is watertight. Hence, we will start by removing any present dust and debris from the area. We also conduct any insulation required for the flooring at this stage below the waterproofing membrane. We place the insulation in 2 layers. We first use dried sand to fill any void around the pipes. We make sure that the sand is level, and then we install the second layer of the insulation board. 3. Laying out the watertight membrane The next step is to lay the waterproof membrane. We use a polyethylene sheeting for this procedure. The sheet ensures that no leakage of the screed occurs when it is pumped in wet on the floor. We either use a 1000 gauge or a thicker 2000 gauge. This is the use of polyethylene as the damp proof membrane (DPM) under your concrete subfloor. The layer is placed immediately under the pipework and above the insulation board. Also, we curl up the polyethylene at the edges of the area that is stuck to the walls. This is the same area that requires screeding. We make sure that the corners are elegant and stuck. We then tape the joins with gaffer tape. You might also require some expansion foam around the edges of your room and others between the wall and the screed when it is poured. The expansion allows the screed to move slightly as it cools and warms and eventually expands. This means that the type of screed used, the amount of screen needed, and the size of the room will determine the foam expansion required. Once we are done, what will be left is a shallow, watertight, polyethylene pool. This is the area where the screed is collected. 4. Waterproofing your shutters You will also require some formwork around some troublesome pipework and obstacles. The aim is to ensure that the screed or water does not get into the pipes or obstacles. We also look for the places in your room that have shutters. Usually, you will find shuttering across steps and doorways. Once the regions are located, we seal them with mastic or expanding foam. The seal ensures that the areas are watertight. Doorways generally require the expansion foam. 5. Securing your underfloor heating pipes If you have underfloor heating, remember to secure the trays and the pipes inside the polyethylene. The clips on the polyethylene will seal automatically. Nevertheless, ensure that nothing will float up once the screed is poured. If you are installing underfloor heating, install them at this stage. Ensure that the heating pipes are clipped after every 400mm and at the bend. Also, fill any underfloor heating pipes with water to stop them from floating. This will also prevent them from being squeezed by the weight provided by the screed. If your heating system is an eggbox type of pipe system, lay the membrane under the eggbox. Also, avoid having small offcuts of the eggbox to prevent the system from floating. Usually, the minimum cover needed above the heating pipes is 30mm. Therefore, the thickness of the screed is at least 50mm when using an underfloor heating pipe of 16mm. PHONE: 0115-824-3549 Common Mistakes to Avoid During Preparation There are two main mistakes to avoid during the preparation process:

When the subfloor has a slope or is uneven, it can cause evident differences in the level of the floor. It can also affect the quantity of the screed needed. Hence, each room needs to be measured appropriately. Certain features should be considered when taking the measurements. They include the door openings, the difference between the height of the floors in different rooms, and the minimum cover and thickness of the space. Also, it is essential to agree on these measurements before the installation process begins with your contractor. All measurements should be marked on the wall to show any comparisons on the levels above the screed once the flooring is complete. Ordering less screed Usually, extra charges are needed for any extra ordered screed. Therefore, in addition to the issues outlined above about flooring problems, ordering less screed will cost you more money. Now that everything is watertight and sealed, you can start pouring your screed. Hire Us Because When you need a professional for your screed preparation process, you should consider hiring our preparation services. By choosing us:

Let us use our skill and time to carry out your preparation by ensuring that the finished product is entirely compatible with the materials used in your building project. We are ready to answer any question you have about preparing your screeding process. Contact us today and get any feedback you want. Relax and let us deal with the stress and worries of the job. Concrete Pumping

Building projects raise several concerns, and concrete pumping is one of them. At Nottingham concrete and screed services, we work to ensure that your concrete pumping concerns are non-existent. Besides, we have an experienced team that delivers fast and clean solutions to your building projects. We are also experienced in bringing you timely and budget-friendly solutions. We offer everything that you will need in a dependable and convenient source. Our vision is to provide you with fast, efficient, and safe pumping services. Delivering quality is an attitude we imbue in the way we run every aspect of our business. PHONE: 0115-824-3549 Our services Our certified workers are trained to deliver the best results with efficiency and exceptional safety standards. Our services will increase the flexibility you require to expand your business and grow your profits. Our services include:

We will cover your entire project without any problems. We aim to put your mind at ease. Our work is not until we make a difference in your job. We are also considerate of the cost you incur for your projects. We strive to be very upfront with our prices and fees. We develop your quote very carefully. We are also concise about our pricing process. Therefore, you can be sure that you will save significant amounts of money when you hire us. Your price will be exact to your needs. Whether you are laying concrete for a large building, a foundation, or an existing building, our services will provide you with the most versatile and accessible solutions. Simple Concrete Solutions We specialize in tight access. As long as a mini-mix truck can access your area, we will provide concrete pumping services. After we are done, your work will be to level and finish the flooring. We can also pump any type of concrete. For instance, we pump liquid screed. We make the most challenging jobs simple by offering additional flowing concrete and fluid screed installation services. We are convenient Our company specializes in the distinctive design and compact concrete line pumping services. We also have mixer units that will work with varied projects. Our concrete pumping services reduce the risk of damaging the door thresholds and driveways, among other regions. Our pumps are also suitable for building work that includes new building properties, foundations, driveway extensions, cellars and flooring, bridges, basements, slabs, subsidence work, and columns, among others. We are professional We are keen to ensure the equipment and service we offer are the best in the market. All our staff members are certified operators. We provide safe and professional services to ensure you are a happy customer. Our Customers We offer our services to residential, government, and commercial projects. We work for:

The Benefits of Concrete Pumping There are several advantages that you can enjoy when using a concrete pump. They include: Saving labour costs Using a concrete pump will allow you to place the concrete where it is needed. Hence, you will require less labour when compared to moving the concrete with buckets, wheelbarrows, and cranes. As a result, your labour costs will reduce significantly. The flexibility of the concrete pump will also remove the need for you to use any other equipment needed to transport the concrete. PHONE: 0115-824-3549 Fast building The concrete pumping process will give you the allowance you need to place an increased cubic meters of concrete every hour. This method is better than others in the market. Our concrete pumping can pump up to 20 m3 every hour. Hence, our work can be valuable, especially if you have a tight building deadline. Less waste The concrete pumping process is very efficient. This is because it carries the concrete to the exact location it is needed. Also, the process is immaculate. Hence, concrete pumping experiences minimal to no spillage or waste. Additionally, all our equipment can pump the concrete in any type of weather. Professional and fully trained operatives Our operatives are fully trained. Therefore, the process of concrete pumping is speedy and efficient. Our expertise and skill will allow your team members to focus on other tasks on the project. Flexibility We offer land lime pumps that will allow you to pump concrete to the inaccessible areas. For instance, our equipment can reach areas where vehicles have restricted access. Besides, the pumps can move around, under, or over obstacles. Therefore, if you want to pump concrete upstairs, in hard to reach areas, or over houses, we have the solution you need. Fresh concrete The advantage of using concrete pumps is that they do not need a lot of water. Therefore, once the concrete is placed, you will experience no cracking or shrinkage. As a result, your concrete will have more extended longevity and stability. The Concrete Pumping Process This is the process of transferring concrete in liquid form to the areas of construction. We specialize in the line pumping process. We also offer a variety of vertical and reach concrete equipment. Concrete pumping is the best solution for you if you have inaccessible areas at the construction site. For instance, if your site is on a steep slope, behind a terraced row, or down a very narrow street, concrete pumping will be your solution. Also, if you do not want to experience the risk of damaging your surrounding areas through spills or the impact of laying concrete, you should consider concrete pumping. The process is much faster and cleaner. We have the equipment and the expertise needed to control costs and maintain the building schedule. We have the necessary products to meet your building requirements. We work with you as partners. Our dedication to your success is tailored to ensure that you have all the assistance you need concerning pumping applications. We also custom design pumping systems for your projects. Our line pumps are capable of pumping concrete in high volumes and through long distances. PHONE: 0115-824-3549 How You Can Arrange For Concrete Pumping If you wish to hire our services, you will need to:

It is natural to want to know how much it will cost you to hire our concrete pumping services. We do not show our prices on our site directly, but we offer a reliable and flexible tariff. Your work is to call our team or book an appointment online. You will then get access to our affordable rates. The total cost depends on your exact needs. Also, your quote will remain reliable throughout your project. Our custom building exercise for different projects is the reason why we do not list our quotes. We also think that this is a great way to let you be in control of your budget. Why You Should Hire Us

Call us today and get more information about our concrete pumping services. You can also visit our site and get a free quote. We have been helping customers with their concrete supplies for years. We give value for money by buying quality concrete and offering excellent pumping solutions. Concrete pumping is not straightforward. That is why we have a team of the best line pump operators in the region. Therefore, leave all the tasking decisions to us. We can take care of all your concrete requirements. Underfloor heating

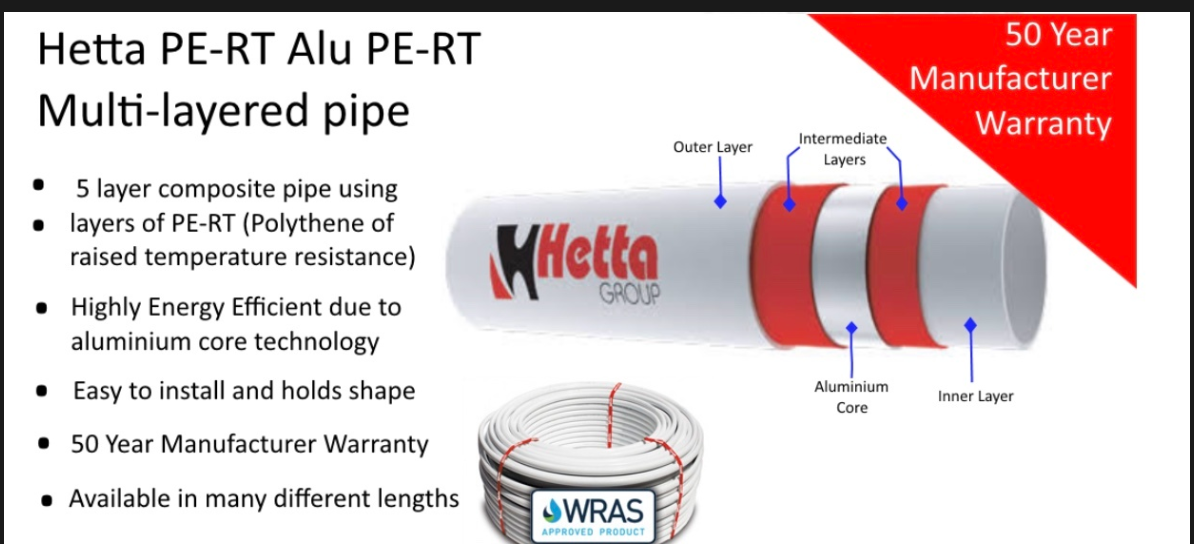

We understand it can be devastating to spend a significant amount of money on building or remodeling your home. Our work is, therefore, to ensure that your underfloor heating system does not disappoint you. That is why we only supply the PE-RT Multi-layered pipe system. This underfloor heating system will turn your floor into a massive source of gentle radiant heat. We work to ensure that by choosing us, every day will be a barefoot day for you. Our services We are flexible. We can retro-fit or install your heating system within a renovation or in a new building project. Our work is to:

We use our heating systems to warm your floor by making them your primary heat source. We specialize in wet underfloor heating systems that replace your radiators. Hence, you will require a heat source and a pump for the system to function correctly. As a result, we use the Hetta PE-RT Alu PE-RT Multi-layered pipe because it is a sturdy and durable product that is also very efficient. This product is designed to suit all properties and different floor types. Installation We have an excellent group of technicians that will start the installation process by developing the design for your property. Each installation process is unique to the property. Our underfloor heating system is also pre-assembled. This makes it easy for us. We either mount the heater on the surface or conceal it within your property. We leave the choice to you. Maintenance Since we use a system that is highly efficient and of superior quality, it will remain intact for an extended period without the need for any intervention. However, if you encounter any problems with your underfloor heating system, we are readily available to answer your questions. PHONE: 0115-824-3549 Contact us on our Nottingham concrete and screed website for any free and friendly advice. We will also send a member of our team to carry out the system maintenance for you if the need arises. Why Underfloor Hearing is necessary Our underfloor heating (UFH) system will ensure that you have consistent room temperatures throughout the year and in every room in your building. Additionally, the systems ensure that you have improved air quality, total temperature control, more room space to use, and energy savings of up to thirty percent. Some other benefits that you will enjoy with our UFH system include:

You will also avoid the presence of cold spots or draft areas when using our heating system because the heat produced by the system warms from the base upwards. Your home will always be a comfortable living environment. The Hetta UFH is also almost completely silent when it is in operation. This means that you can lose the worry of having a noisy machine in your home. Besides, we can fit the system in any type of home or floor construction. We can also integrate our heating system with any other already present heat source in your building. Once we are done, the only thing you will need to worry about is how to control your thermostat. Our heating system The Hetta PE-RT Alu PE-RT, underfloor heating system, is broken down into three primary parts:

The multi-layered pipe The Hetta pipe is made from a five-layer composite Polyethylene of Raised Temperature resistance material. Its aluminum core technology is 0.2mm thick with butt-welded construction. This makes it very energy efficient. The pipe operates at a maximum temperature of 70 degrees. The pipe will also hold its position making the installation process straightforward. It is also a product that is WRAS approved. The pipe comes in 100, 200, 150, and 500 mm coil lengths. It is very flexible and lightweight. PHONE: 0115-824-3549 The pre-assembled manifold The Hetta underfloor heating system has a nickel-plated pre-assembled manifold. It comes in a complete package of adjustable flow meters, automatic air vents, isolation ball valves, fill and drain points, and pipe connectors. The pipe connectors are available for 15mm and 15m pipes. This manifold can be mounted on the surface or concealed in a place that you choose. The types of thermostats Our Hetta underfloor heating system has a wide range of controls and wiring centres that you can use to control your heating. Our extensive range of mains include wired, wireless, and Wi-Fi thermostats.

Our standard choice Our standard thermostat is the Heatmiser slimline thermostat. It is powered by 230v, it combines the room stat and programmer, and it can be controlled from multi zones. Our system is cheap to run, it can fit large areas, and it can be installed in many rooms. Hetta also comes with a 50-year manufacturer’s warranty. How We Operate Once you have hired our services, we will visit your site so that we can study your design. Our goal is to tailor-make any system to suit your requirements. During the site visit, we discuss your options and measure up space in your compound. We start by determining your floor construction type. Three types of floor constructions exist:

Sold floor construction Here, we lay the underfloor heating system onto the insulation layer before we pour the screed. This ensures that the pipe is contained within the floor structure. The advantage of using this system is that it ensures the depth of the floor structure is maintained as it was before the installation of the heating system. The system provides an excellent output on concrete. It is also the most effective method of UHF. Suspended floor construction These floor types include concrete floors with fixed battens and joisted floors. The best Hetta products used in this type of floor are the Hetta aluminum spreader plates. We insulate the void floor with mineral wool insulation or loose-fill insulation. We also minimize the airflow to ensure heat is not lost. We can also cut the plates to fit your irregular joist widths. This system is perfect because it is easy to install, it is very lightweight, it has excellent thermal conduction, and it is ideal for 400mm sized standard hoists. PHONE: 0115-824-3549 Floating or existing floor construction If what you need is a retro fit solution for your existing floor areas, this is the system we use. We use the extruded polystyrene panels. They are coated with foil. The panels also have a low thermal mass. They will respond to the changes in temperatures swiftly. You will also require no extra fittings with this design. The design will only raise your floor by 25mm. It is easy to cut and lightweight, and it is commonly laid directly on the floor. Once we have determined your floor construction type and the heating design you need, we will provide you with a free bespoke CAD drawing of your underfloor heating system. We believe that no system is too complicated for our team. Therefore, we guarantee that all your needs will be fulfilled. Why choose us From your initial phone call to the final inspection after the installation process, we are present to help you throughout the project. You are our boss; we only do as much or as little as you want.

PHONE: 0115-824-3549 Auburn concrete company |

We cover quite a wide radius of around 70 miles from Junction 28-29 of the M1

Nottinghamshire Derby Leicestershire South Yorkshire Cheshire Staffordshire We do travel further but always ring first to confirm |